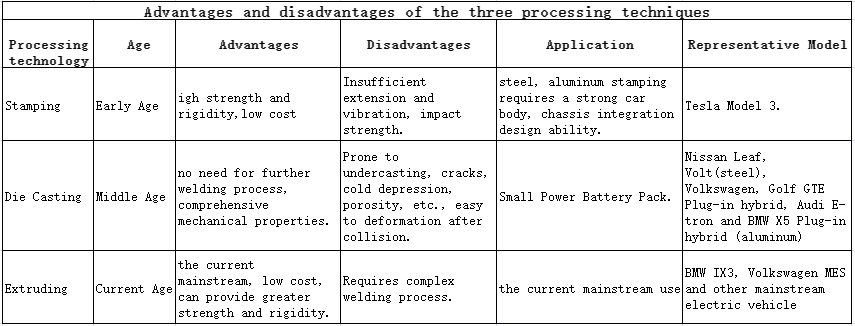

Māhele 2. ʻenehana: alumini extrusion + friction stir welding e like me ka mainstream, laser welding a me FDS a i ʻole e lilo i alakaʻi e hiki mai ana

1. Hoʻohālikelike ʻia me ka hoʻolei ʻana a me ka hoʻopaʻa ʻana, alumini extrusion e hana ana i nā profiles a laila wili ka ʻenehana nui o nā pahu pākaukau i kēia manawa.

1) ʻO ka hohonu o ke kaha kiʻi o ka pūpū ma lalo o ka pahu pākahi i hoʻopaʻa ʻia e ka pā alumini stamping, ʻaʻole lawa ka haʻalulu a me ka ikaika o ka hopena o ka pā pākaukau, a me nā pilikia ʻē aʻe e koi ai i nā ʻoihana kaʻa e loaʻa i ka mana hoʻolālā ikaika o ke kino a me nā chassis;

2) ʻO ka pahu pahu pahu alumini i loko o ke ʻano hoʻoheheʻe make e hāpai i ka hoʻoheheʻe ʻana i hoʻokahi manawa.ʻO ka hemahema, ʻo ka alumini alumini ka mea maʻalahi i ka undercasting, nā māwae, ka hoʻokaʻawale anuanu, ke kaumaha, ka porosity a me nā hemahema ʻē aʻe i ke kaʻina hoʻolei.He ʻilihune ka waiwai hoʻopaʻa ʻana o ka huahana ma hope o ka hoʻolei ʻana, a he haʻahaʻa ka elongation o ka alumini alumini, hiki ke hoʻololi ʻia ma hope o ka hui ʻana;

3) ʻO ka pahu pahu pahu pahu alumini extruded ʻo ia ka papa hana hoʻolālā pākaukau nui o kēia manawa, ma o ka splicing a me ka hana ʻana o nā profiles e hoʻokō i nā pono like ʻole, loaʻa nā pono o ka hoʻolālā maʻalahi, ka hana maʻalahi, maʻalahi e hoʻololi a pēlā aku;Performance Extruded alumini alumini pā pākaukau he kiʻekiʻe rigidity, vibration kū'ē, extrusion a me ka hopena i ka hana.

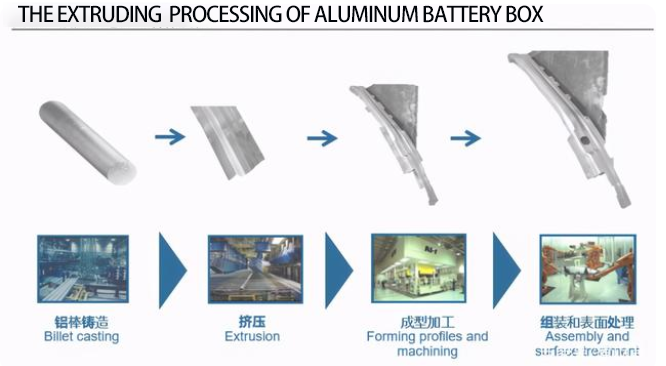

2. ʻO ka mea kikoʻī, ʻo ke kaʻina hana o ka extrusion alumini e hana i ka pahu pahu pahu penei:

Hoʻokumu ʻia ka papa lalo o ke kino pahu e ka friction stir welding ma hope o ka hoʻokuʻu ʻia ʻana o ka pahu alumini, a ua hoʻokumu ʻia ke kino pahu lalo e ka wili me nā ʻaoʻao ʻehā.I kēia manawa, hoʻohana ka ʻōnaehana alumini maʻamau i ka 6063 a i ʻole 6016, ʻo ka ikaika tensile ma waena o 220 ~ 240MPa, inā ka hoʻohana ʻana i ka alumini extruded ikaika kiʻekiʻe, hiki i ka ikaika tensile ke piʻi aku ma mua o 400MPa, ke hoʻohālikelike ʻia me ka pahu profile alumini maʻamau hiki ke hōʻemi i ke kaumaha e 20%~30%.

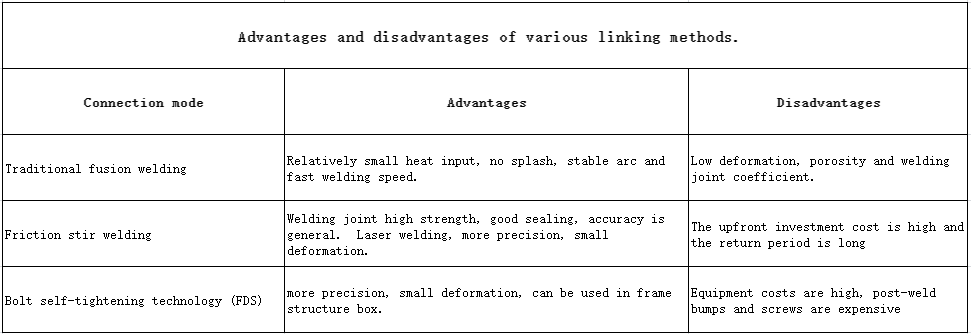

3. Ke hoʻomaikaʻi mau nei ka ʻenehana welding, ʻo ke kumu nui o kēia manawa he friction stir welding

Ma muli o ka pono e hoʻopili i ka ʻaoʻao, he hopena nui ka ʻenehana welding i ka palahalaha a me ka pololei o ka pahu pākahi.Hoʻokaʻawale ʻia ka ʻenehana wili pahu pahu pahu i ka kuʻuna kuʻuna (TIG welding, CMT), a i kēia manawa ʻo ka mainstream friction welding (FSW), ʻoi aku ka maikaʻi o ka hoʻoheheʻe ʻana i ka laser, ka ʻenehana hoʻopaʻa paʻa ponoʻī (FDS) a me ka ʻenehana paʻa.

Aia ʻo TIG welding ma lalo o ka pale o ke kinoea inert, me ka hoʻohana ʻana i ka arc i hana ʻia ma waena o ka tungsten electrode a me ka weldment e hoʻoheheʻe i ka metala kumu a hoʻopiha i ka uea, i mea e hana ai i nā welds kiʻekiʻe.Eia nō naʻe, me ka hoʻololi ʻana o ka hoʻolālā pahu, ʻoi aku ka nui o ka pahu, ʻoi aku ka lahilahi o ke ʻano o ka ʻaoʻao, a ʻoi aku ka pololei o ke ana ma hope o ka hoʻopili ʻana, ʻoi aku ka maikaʻi o ka wili ʻana o TIG.

ʻO CMT kahi kaʻina hana kuʻihao MIG/MAG hou, me ka hoʻohana ʻana i kahi manawa pulse nui e hana maʻalahi ai ka uea kuʻi ʻana, ma o ke ʻano o ka ʻili o ka ʻili, ka umekaumaha a me ka pumping mechanical, e hana ana i kahi weld mau, me ka hoʻokomo wela liʻiliʻi, ʻaʻohe splash, arc stability a ka wikiwiki wiliwili wikiwiki a me nā pono ʻē aʻe, hiki ke hoʻohana ʻia no nā ʻano mea like ʻole.No ka laʻana, ʻo ka hoʻolālā pahu ma lalo o ka puʻupuʻu pākaukau i hoʻohana ʻia e nā hiʻohiʻona BYD a me BAIC e hoʻohana i ka ʻenehana welding CMT.

4. Loaʻa nā pilikia e like me ka deformation, porosity a me ka coefficient hui pū kuʻi kuʻuna ma muli o ka hoʻokomo wela nui.No laila, ʻoi aku ka maikaʻi a me ka ʻōmaʻomaʻo friction stir welding ʻenehana me ka kiʻekiʻe o ka maikaʻi wili i hoʻohana nui ʻia.

Hoʻokumu ʻia ʻo FSW i ka wela i hana ʻia e ka friction ma waena o ka ʻili hui ʻana a me ka poʻohiwi kumu a me ke kumu metala e like me ke kumu wela, ma o ka hoʻololi ʻana o ka nila hui ʻana a me ka ikaika axial o ka poʻohiwi kumu e hoʻokō ai i ka kahe plasticization o ka. metala kumu no ka loaʻa ʻana o ka hui kuʻi.Hoʻohana nui ʻia ka hui kuʻi ʻana o FSW me ka ikaika kiʻekiʻe a me ka hana hoʻopaʻa inoa maikaʻi ma ke kahua o ka pahu pahu pahu.No ka laʻana, ʻo ka pahu pākaukau o nā hiʻohiʻona he nui o Geely a me Xiaopeng e hoʻohana i ka ʻaoʻao lua ʻaoʻao friction stir welding structure.

Hoʻohana ʻo Laser welding i kahi kukuna laser me ke kiʻekiʻe o ka ikehu kiʻekiʻe e hoʻomālamalama i ka ʻili o ka mea e welded e hoʻoheheʻe i ka mea a hana i kahi hui hilinaʻi.ʻAʻole i hoʻohana nui ʻia nā lako welding laser ma muli o ke kumukūʻai kiʻekiʻe o ka hoʻopukapuka mua ʻana, ka wā hoʻihoʻi lōʻihi, a me ka paʻakikī o ka welding laser alumini.

5. No ka hoʻohaʻahaʻa ʻana i ka hopena o ka deformation welding ma ka pololei o ka nui o ka pahu, hoʻokomo ʻia ka ʻenehana hoʻopaʻa paʻa ponoʻī (FDS) a me ka ʻenehana hoʻopaʻa ʻana, ma waena o nā ʻoihana kaulana ʻo WEBER ma Germany a me 3M ma ʻAmelika Hui Pū ʻIa.

ʻO ka ʻenehana pili FDS kahi ʻano hana anu o ka hoʻopaʻa ʻana iā ia iho a me ka pilina bolt ma o ka hoʻopaʻa ʻana i ke kumu o ke kikowaena mea hana e hoʻokō ai i ka holo kiʻekiʻe o ka mīkini e hoʻopili ʻia i ka wela friction plate a me ka deformation plastic.Hoʻohana maʻamau ia me nā robots a he kiʻekiʻe kiʻekiʻe o ka automation.

Ma ke kahua o ka hana hou ʻana o ka pā uila, ua hoʻohana nui ʻia ke kaʻina hana i ka pahu hoʻolālā frame, me ke kaʻina hana hoʻopaʻa, i mea e hōʻoia ai i ka ikaika pili i ka wā e ʻike ai i ka hana hoʻopaʻa ʻana o ka pahu.No ka laʻana, hoʻohana ka pahu pākahiko o kahi ʻano kaʻa o NIO i ka ʻenehana FDS a ua hana nui ʻia.ʻOiai ua loaʻa i ka ʻenehana FDS nā pōmaikaʻi, aia kekahi mau hemahema: ke kumukūʻai kiʻekiʻe o ka lako, ke kumu kūʻai kiʻekiʻe o nā protrusions post-weld a me nā screws, a me nā mea ʻē aʻe, a me nā kūlana hana e kaupalena ʻia kāna noi.

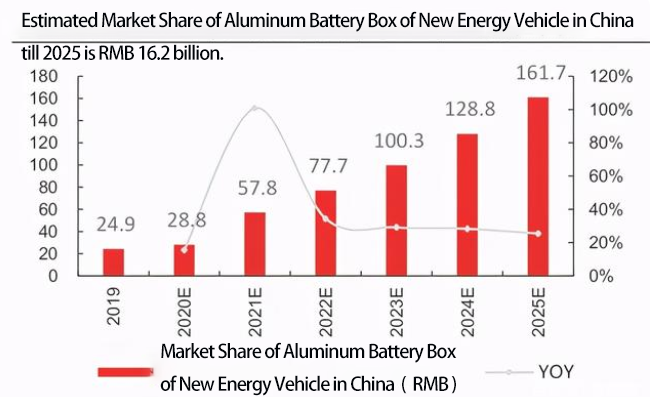

Māhele 3. Māhele Mākeke: nui ka nui o ka mākeke pahu pahu pahu, me ka ulu wikiwiki o ka hui

Ke hoʻomau nei ka hoʻonui ʻana o nā kaʻa uila maʻemaʻe i ka nui, a ke ulu wikiwiki nei ka mākeke o nā pahu pākahi no nā kaʻa ikehu hou.Ma muli o nā manaʻo kūʻai kūʻai kūloko a me ke ao holoʻokoʻa o nā kaʻa ikehu hou, helu mākou i ka mākeke kūloko o nā pahu pahu pākahi kaʻa ikehu hou ma o ka manaʻo ʻana i ka awelika o kēlā me kēia ʻāpana waiwai o nā pahu pahu uila hou.

Nā manaʻo kumu:

1) ʻO ka nui o ke kūʻai ʻana o nā kaʻa ʻenehana hou ma Kina i 2020 he 1.25 miliona.Wahi a ka Medium and Long-term Development Plan of Automobile Industry i hoʻopuka ʻia e nā Kuhina ʻekolu a me nā komisina, he mea kūpono ke manaʻo ʻia ʻo ka nui o ke kūʻai aku ʻana o nā kaʻa kaʻa kaʻa hou i Kina i ka makahiki 2025 e hiki i 6.34 miliona, a me ka hana ʻana o nā mea hou i waho. hiki i nā kaʻa ikehu 8.07 miliona.

2) ʻO ka nui o ke kūʻai aku ʻana o nā kaʻa uila maʻemaʻe he 77% i 2020, me ka manaʻo he 85% ka nui o ke kūʻai aku ma 2025.

3) Mālama ʻia ka permeability o ka pahu pahu pahu alumini alumini a me ka bracket ma 100%, a ʻo ka waiwai o kahi kaʻa hoʻokahi he RMB3000.

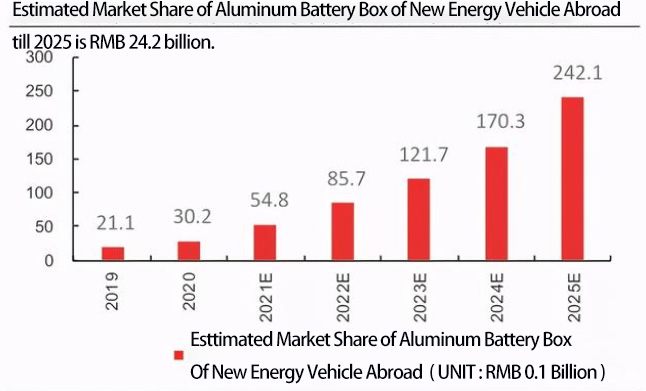

Nā hualoaʻa helu: ua manaʻo ʻia e 2025, ʻo ka mākeke o nā pahu pākahi no nā kaʻa kaʻa kaʻa hou ma Kina a me nā ʻāina ʻē e pili ana i RMB 16.2 biliona a me RMB 24.2 biliona, a ʻo ka ulu ʻana o ka hui mai 2020 a 2025 he 41.2% a. 51.7%

Ka manawa hoʻouna: Mei-16-2022